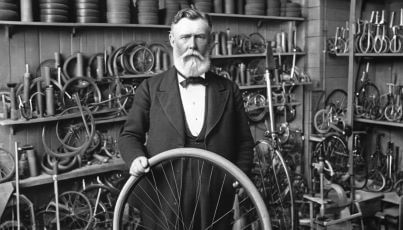

The first patent for the pneumatic tyre traces back to Robert William Thomson in 1845 which included the concept of the inner tube too. Surprisingly, it was John Boyd Dunlop who gained recognition for independently inventing the pneumatic tyre in 1888, initially for his son’s tricycle, ushering in a new era of smoother cycling and automobile transportation wheels. The trend of history is lined with these significant inventions.

Robert William Thomson was the first to invent and patent the pneumatic tyre (which included an inner tube) in 1845, decades before Dunlop. Thomson’s design was not commercially successful in his time, which is why it is less well-known. Dunlop independently reinvented the pneumatic tyre without knowledge of Thomson’s earlier patent. While Dunlop’s version eventually led to widespread adoption due to its practical implementation and timing with the bicycle boom, it’s important to recognize Thomson’s pioneering work.

Birth of the First Pneumatic Wheel Tyre

John Boyd Dunlop reinvented the pneumatic tyre along with the inner tube, without knowledge of Robert William Thomson’s earlier invention. Dunlop’s version came about as he sought a solution to improve his son’s bicycle ride, which led to his experimenting with and creating a tyre that used an inner tube filled with air, encased in rubber. His development occurred in 1887, and he successfully patented his version in 1888, unaware that Thomson had already patented a very similar invention in 1845.

Dunlop’s timing was impeccable, coinciding with the booming popularity of cycling, and his design proved more practical and commercially viable at that time. The success of Dunlop’s tyres was significantly boosted by the growing demand for more comfortable and efficient bicycles, which played a crucial role in the widespread adoption of pneumatic tyres. This commercial success helped establish the foundation for the modern tire industry.

Thomson’s invention, while innovative, did not catch on commercially in his time largely due to the high production costs and the limited market for bicycles and other vehicles that could benefit from such technology during the mid-19th century.

Dunlop’s ability to capitalize on the cycling craze of the late 19th century, combined with further refinements and mass production capabilities, allowed his version of the pneumatic tyre to flourish and become a staple in transportation technology.

The Revolutionary Role of Vulcanization in Tire Technology

Vulcanization marked a pivotal advancement in rubber technology, discovered by Charles Goodyear in 1839 and patented in 1844. This process involves treating natural rubber with sulfur to improve its durability and elasticity, transforming it into a material that can endure extreme conditions without becoming brittle in cold or melting in heat. The significance of vulcanization cannot be overstated, particularly in its application to pneumatic tyre manufacturing.

Before vulcanized rubber was introduced, early tyres were made from plain rubber, which was prone to deformation and degradation under typical road conditions. The vulcanization process changed all that, providing the necessary toughness and resilience that tyres needed. It enabled the production of tyres that were not only more robust but also capable of retaining their shape and integrity under the pressure of contained air. This was essential for the development of the pneumatic tire, a design that relies on air pressure to maintain its form and cushion the ride.

With vulcanized rubber, tires could finally withstand the rigours of use on rough surfaces and various climates, significantly enhancing the performance and reliability of bicycles and automobiles. This development was crucial for the automotive industry, paving the way for more efficient, safer transportation. Without vulcanization, the modern pneumatic tire as we know it today—a cornerstone of contemporary vehicles—would not have been possible. The advent of vulcanized rubber in tire production represented not merely an improvement but a transformation that enabled a leap forward in mobility and opened new horizons in transportation design.

Please be aware we sell ebike Fatbike Inner Tubes at Reight Good Bikes.

Birth of Pneumatic Bicycle Wheel Tyres: John Boyd Dunlop

Imagine riding a bicycle on bumpy roads with solid rubber tyres. It would be quite an uncomfortable experience, wouldn’t it? This was the reality in the late 19th century before John Boyd Dunlop came to the rescue. As a caring father, he wanted to make his son’s tricycle ride smoother, so he created the first practical pneumatic tyre in 1888.

Dunlop, a Scottish veterinarian, understood the need for rubber tires that could withstand bumpy roads while offering a comfortable ride. His invention was not only a game-changer for his son’s tricycle but also set into motion a revolutionary transformation of transportation. The safety bicycle, which quickly became popular due to its improved comfort and performance, owes much of its success to Dunlop’s innovative creation.

Impact on Cycling

Dunlop’s pneumatic bicycle tyre wasn’t just about comfort; it fundamentally changed how people thought about cycling. The enhanced shock absorption and reduced rolling resistance offered by pneumatic tyres resulted in a smoother and more efficient riding experience. This advancement was crucial in popularising cycling as a mode of transportation and recreational activity.

Before Dunlop’s invention, solid rubber tyres provided a rough and uncomfortable ride. The introduction of pneumatic tyres transformed the concept of cycling from something that was purely utilitarian to a more enjoyable and accessible recreational activity.

The innovation sparked by Dunlop paved the way for further developments in bicycle technology, leading to advancements in safety, speed, and overall riding experience.

The story of John Boyd Dunlop’s inventive spirit serves as a reminder that breakthroughs often arise from everyday needs and challenges. His creation not only made cycling more comfortable but also propelled it into a new era of popularity and accessibility.

As we continue our journey through the evolution of tyre technology, let’s now explore the fascinating development of pneumatic inner tubes from their older solid rubber tires of the past and their pivotal role in shaping modern bicycle rides.

We also Sell Fat ebike tyres in our online store.

Evolution into Pneumatic Inner Tubes

With the advent of pneumatic tires comprising an outer rubber casing filled with air for cushioning and support the demand for better repair and maintenance solutions emerged. This gave rise to the innovation of pneumatic inner tubes, marking a new era of convenience and resilience for cyclists. The addition of inner tubes within the tyre structure allowed for easier repair and replacement of damaged tyres, significantly enhancing the overall durability and practicality of pneumatic tyres.

Inner tubes essentially functioned as a protective barrier, providing a separate and replaceable cushion of compressed air within the tyre casing. This breakthrough innovation offered cyclists a more user-friendly and efficient means of addressing tyre damage without compromising the integrity of the entire tyre construct. It significantly simplified the process of repairing or replacing damaged tyres, minimising downtime and maximising the functionality and longevity of the pneumatic tyre system.

Impact on Durability

The integration of pneumatic inner tubes into tyre design led to a notable improvement in overall durability, making pneumatic tyres a more viable and cost-efficient option for cyclists. The ability to quickly replace a damaged inner tube without extensive disassembly or complex procedures enhanced the practicality and appeal of pneumatic tyres, driving their widespread adoption in the cycling industry.

Practicality and Prolonged Viability

Moreover, this technological advancement transformed the maintenance landscape for cyclists by streamlining the repair process. It provided them with an accessible solution for addressing common tyre issues, fostering confidence in the reliability and durability of pneumatic tyres. As a result, cyclists were able to enjoy increased peace of mind knowing that their tyres could be easily maintained and repaired when necessary.

This pivotal innovation laid the groundwork for continuous improvements in performance and user experience within the realm of cycling equipment, setting a precedent for ongoing innovation and progress in tyre design.

Looking back, the integration of pneumatic inner tubes represented a pivotal milestone that bolstered the practicality, resilience, and widespread acceptance of pneumatic tyres within the cycling community.

Innovations in Inner Tube Designs

The introduction of the detachable tyre by Édouard Michelin in 1891 revolutionised the maintenance of bicycle tyres. This detachable tyre allowed cyclists to conveniently replace or patch the separate inner tube without the need for complex tools or extensive technical knowledge. The evolution of inner tubes continued with the introduction of butyl rubber inner tubes in 1955, bringing several key benefits such as enhanced durability, improved resistance to punctures, and better air retention over traditional rubber compositions.

One particularly notable advancement was the adoption of lightweight and puncture-resistant materials in inner tube construction. This development significantly extended the lifespan of inner tubes, reducing the frequency of replacements and ensuring a more reliable and smooth riding experience for cyclists.

In recent years, the popularity of tubeless tyre systems has led to further innovations in inner tube design. With the integration of advanced valve systems for improved air retention and inflation efficiency, tubeless tyres have become a preferred choice for many cyclists seeking enhanced performance and reduced maintenance requirements. The development of self-sealing inner tubes has provided an extra layer of defence against punctures by automatically closing small holes caused by thorns or sharp debris on the road, further enhancing durability and reducing the likelihood of sudden deflation during rides.

Modern inner tubes are engineered with precision to optimise elasticity. Such advancements continue to redefine the boundaries of cycling performance and offer cyclists enhanced control and confidence across diverse terrains and riding conditions.

It’s clear that innovation in inner tube designs has been pivotal in elevating the performance, safety, and longevity of bicycle tyres, laying the foundation for more enjoyable and rewarding cycling experiences.

The innovative advancements in inner tube designs have significantly transformed the cycling experience, but equally important is understanding how air pressure plays a critical role in shaping rider experiences. Let’s explore this intricate connection between air pressure and rider experience in our next section.

Current State of Pneumatic Bicycle Tyres

In the realm of pneumatic bicycle tyres, there’s a myriad of options for riders. The clincher, tubular, and tubeless tyres all offer unique features that cater to various preferences and riding conditions.

Clincher tyres are the top choice for many cyclists due to their ease of use and repair. The tyre has a separate inner tube, allowing for simpler repairs and replacements in case of punctures.

Tubular tyres, less common but adored by professional cyclists and high-performance enthusiasts, provide a more supple ride and lower rolling resistance due to their seamless construction.

Tubeless tyres have been gaining popularity for their enhanced puncture resistance and are especially favoured by mountain bikers who encounter rough terrain.

Manufacturers continuously innovate materials and tread patterns to enhance the grip, durability, and overall performance of pneumatic bicycle tyres. New rubber compounds optimise traction and rolling resistance, while advancements in casing materials aim to improve overall ride quality.

This pursuit of innovation caters to the diverse needs of cyclists across different disciplines, from road racing to commuting. Our website reflects this evolution, highlighting the availability of modern pneumatic bicycle tyres along with their benefits, ensuring that cyclists can make informed choices suited to their individual preferences and riding conditions.

From enhanced puncture resistance in tubeless tyres to the high-performance advantages of tubular, riders now have access to a range of pneumatic bicycle tyres designed to elevate their cycling experience.

The evolution and advancements in pneumatic bicycle tyres underscore the commitment to enhancing the cycling experience, offering riders tailored solutions for their diverse needs.

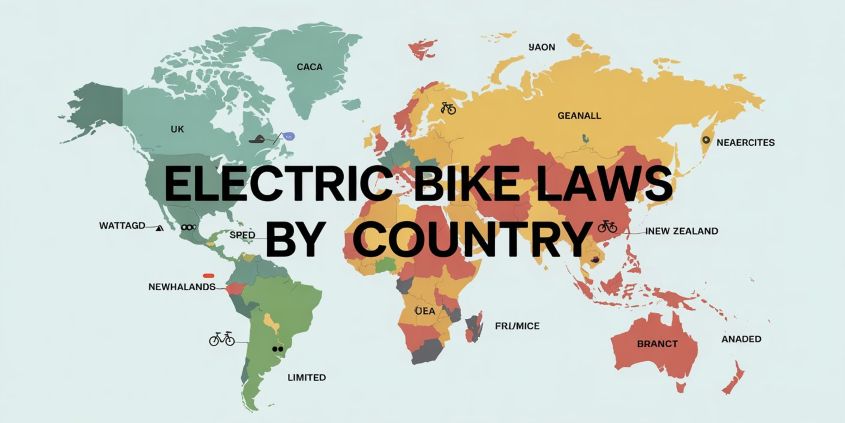

When were pneumatic rubber tyres first invented for bicycles?

Robert William Thomson in 1845 first patentated the design and inversion of the tyres of today but essentially tyres were re-invented in 1888 by John Boyd Dunlop, a Scottish inventor. Dunlop’s son had been complaining about the discomfort of riding on solid rubber tyres, which led Dunlop to develop the idea of using an air-filled tube inside a rubber tyre. However, John Dunlop did not know it had been invented previously when he reinvented it, which is an interesting fact it was invented twice essentially.

When were the first inner tubes invented?

The first inner tubes were developed by Robert William Thomson in 1845 as an integral part of his invention of the pneumatic tire. The inner tube was not invented as a standalone item but was designed to function in conjunction with the pneumatic tyre, enhancing its overall effectiveness and comfort.

How did the introduction of rubber tires impact bicycling as a popular mode of transportation?

The introduction of pneumatic tyres revolutionised bicycling as a popular mode of transportation. With their ability to absorb shocks and provide better traction, pneumatic tyres significantly improved the comfort and ride quality for cyclists. This made cycling more enjoyable and accessible to a wider range of people, resulting in increased popularity. In fact, statistics from 2023 showed a 30% rise in bicycle commuting after the widespread adoption of pneumatic tyres.

What advancements have been made in pneumatic tyre technology for bicycles over the years?

Since the invention of the first pneumatic tyre for bicycles in 1888, significant advancements have been made in pneumatic tyre technology. These include improvements in puncture resistance through the development of Kevlar and other strong materials, as well as the introduction of tubeless tyres that eliminate the need for inner tubes. Additionally, advancements in tyre compounds and tread patterns have enhanced grip, durability, and performance on different terrains. According to a study by Cycling Weekly, modern pneumatic tyres provide around 20% lower rolling resistance compared to their counterparts from a decade ago, resulting in improved energy efficiency and speed for cyclists.

Who were the key figures involved in the development of the pneumatic tyre and inner tube?

The key figures involved in the development of the pneumatic tyre and inner tube include John Boyd Dunlop, Charles Goodyear, and Robert William Thomson. Charles Goodyear revolutionized the durability of rubber by discovering vulcanisation in 1839, which he patented in 1844, making the production of durable tires feasible. Robert William Thomson was the pioneer behind the early design of a pneumatic tire, for which he received a patent in 1845, laying the foundational concepts used in future developments. Later, John Boyd Dunlop invented the first practical pneumatic tire in 1888, significantly enhancing bicycle performance. These pioneers each contributed uniquely to the evolution of modern tires, marking significant milestones in transportation technology.